The Product MANT

Starting-point for the developement of the PCD MANT was to create a recipe of high-purity and homogeneous raw materials especially of the applied diamond micron powders.

1. Chemical purity

The diamond powders used for the MANT products are of very high purity. Especially impurities by the relatively heavy atoms like iron, mangan and nickel with total less than 70 ppm (pars per million) is extremely low.

| ICP-analysis of the diamond powder used for the fine-grain 5-micron MANT PCD products: | ||||||

| Na | Al | Ca | Fe | Mn | Ni | Si |

| 19.4 ppm | 21.4 ppm | 96.2 ppm | 44.3 ppm | 6.46 ppm | 8.17 ppm | 11.2 ppm |

Description of the analysis methodes see here: www.leemanlabs.com

2. Coherency of the applied micro-diamond powders

This diamond powder is used for the manufacturing of the fine-grain MANT PCD.

The partition of particles > 6,5 micron is below 0,2 %. Disturbing particles of bigger size are practically not present. This limitation in size guarantees a homgeneous structure for the entire inner surface of the drawing tool.

Thus the perfect surface of the produced wire.

As well in the partical size range below 2,5 micron only 0,2 % are measured. Result: checkless penetration (soaking) by the liquid cobalt during the high-pressure sintering process.

Details of the applied method see under www.malvern.de

The partition of particles > 6,5 micron is below 0,2 %. Disturbing particles of bigger size are practically not present. This limitation in size guarantees a homgeneous structure for the entire inner surface of the drawing tool.

Thus the perfect surface of the produced wire.

As well in the partical size range below 2,5 micron only 0,2 % are measured. Result: checkless penetration (soaking) by the liquid cobalt during the high-pressure sintering process.

Details of the applied method see under www.malvern.de

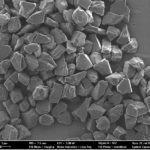

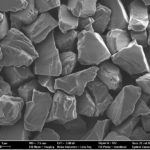

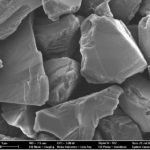

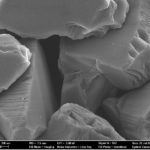

Characteristics: uniform blocky structure of the single grains. Together with the small scattering of the grain size this results in unhindered penetration of the liquid phase during the sintering process.

A view of the same micron diamond-powder with different magnifications: