…. and what’s inside?

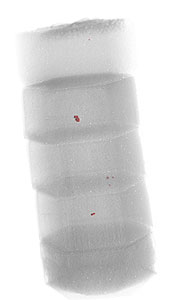

Much improved is this by RCT. The non-destructive computer-tomographic X-ray leads to a

3-dimensional description of impurities. Inner defects in the range of 0,01 mm are visible

and can be found once more in the course of the following treatment by laser and ultrasonic. General description of the RCT methode can be found here: (PDF-file)

The dots in these photo are:

1. Agglomerations (clusters) and vacuoles effected by uneven infiltration with the sintering material (cobalt)

2. Inclusions, impurities

The pcd samples shown in the images 1-5 are each 3-6 pieces of the same kind fixed together for the RCT inspection. The samples taken by random come from the most renowned manufacturers.

>PDF – Download – Quality Comparison of the samples 1-5

|

|

|

|

|

| Sample 1 | Sample2 | Sample3 | Sample4 | Sample5 |